- Green Power Grid

- Electric Power Development

- Mineral Operation

- Industrial Park Development

- Concessions

- Financial Investment and Holdings

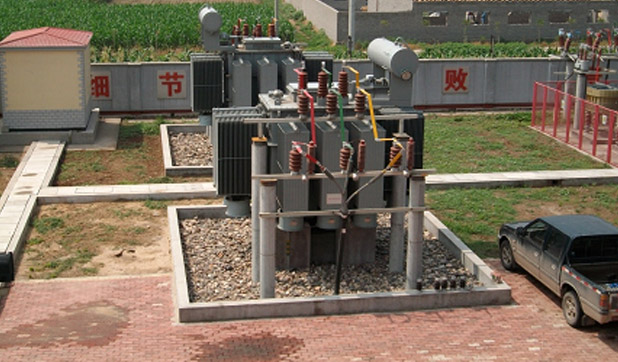

MSVC (Magnetically-controlled Static Var Compensation Device) type

Magnetically controlled static var compensation device, here by simply called MSVC devices are mainly used in 6~110 kV power network system. They can automatically adjust thyristor controlling angle of the MCR, change DC value of the winding and to control saturation of the iron core, to achieve continuous adjustability of the of the winding and then to achieve rapid compensation function of the reactive power. Branches of capacitor in MSVC devices can choose filter capacitor bank, so as to filter harmonic wave, improve power quality of the system. This product has been widely applied in industries as below:

Iron, Steel and Metallurgy

Mineral hot furnace and refined furnace in the metallurgical plant: in the melting process of the mineral hot furnace, electric arc frequently appears and disappears due to frequent ups and downs of the electrode and the three phases are asymmetric. Reactive power of the load fluctuates much and changes rapidly, often causing voltage fluctuation and flickering in the public joints. Meanwhile, current wave of the load is in disorder, containing harmonic components such as twice, 3 times, 4 times and 5 times, affecting normal operation of the power supply system and user facilities. In addition, loading power factor of the mineral hot furnace is relatively low while the common reactive power compensation device can not follow change speed of the loading, making the compensation effect bad and leading to submitting a certain amount of penalty of some electric arc furnace enterprises. MSVC devices can completely solve problems as above, to improve the power factor to be above 0.98.

Rolling mill of the steel plants: in operation period of the rolling mill, loading of the rolling mill shall fluctuate due to uncontinuity of the rolled material. When there is something to be milled, loading of the rolling mill is relatively heavy while the load is zero if no material was supplied. Therefore, the loading capacity of the rolling mill appears rapid change characteristics like a jumping ladder. Power load and powerless load changes greatly and the period is relatively short, generally in several minutes, and the traditional compensation devices are not able to track the compensation. Power factor of the enterprises is relatively low, voltage of the generatrix fluctuates rapidly, then MSVC devices are most suitable for the compensation.

Large hoisting machines in the coal mine, dockyard and port

Hoister usually carries work load in short time; there are several stages such as acceleration, constant speed, speed reduction and stopping; the power required in different stages is different and changes fast, but the powerless compensation devices cannot follow change speed of the load, unable to display the powerless compensation function. However, its hoisting machine is generally DC speed regulating motor. Large amount of harmonic current is contained in the load current and the harmonic current shall be filtered.

Wind Power Generating Field

Generating power of the wind driven generator fluctuates frequently due to frequent change of the wind force in the wind power generating field. Currently, the widely applied asynchronous wind power generator needs to absorb a part of inductive reactive power to establish the magnetic field, which can be satisfied via bridging condenser. However, capacity of the common cast-cut type compensation capacitor cannot satisfy the requirement of frequent powerless fluctuation of the draught fan due to change of the wind force. In case the capacitor cannot be satisfied, the draught fan would absorb powerless power from the power grid, leading to reducing of the power factor of the upper level power grid and fluctuation of the voltage. To guarantee voltage stability of the wind farm, application of MSVC devices shall be wider and wider.

Electrified Railway

Traction load of the electrified railway is a typical super power impact load. When there is no locomotive in the traction area, the traction transformer is almost in zero load condition; when there is locomotive passing by, load of the traction transformer improves fast and then turns down rapidly. If no traced compensation was provided in time, the power factor of the transformer would be relatively lower, the loss increased, causing voltage fluctuation and flickering. Traction system of the electrified load provides power in single phase, which is an asymmetric load, containing lots of components in negative sequence, largely affecting motors nearby; moreover, there are rectifying installations with great capacity on the locomotives, and this will introduce harmonic pollution to the stage grid. Therefore, application of MSVC devices in the traction transformer will compensate power loss in real time, reduce the imbalance degree of the three-phase load and filter the harmonic wave.

Secondary Transformer in Urban Areas

In regional power grid, a hierarchical switched capacitor unit is generally applied to compensate power loss of the system and improve the power factors. This way can only provide capacitive reactive power to the system and cannot achieve fast and precise adjustment with the load. In the mean time when guaranteeing bus power factor, results such as reverse-delivering the power, improving bus voltage, harming the power consumption equipments and the system stability will be caused. MSVC devices can help powerless compensation and capacity compensation in a very fast and precise way, and powerless problems can be completely solved while stabilizing the bus voltage and improving the power factor.

Large hoisting machines in the coal mine, dockyard and port

Wind power generating field

Electrified railway

‘zero’leakage: all insulators of oil-type product inside the capacitor bank generally apply rolling contact casing pipe and no leakage was guaranteed.

Lifelong anti-corrosion: material of enclosure of the attachments is stainless steel. The equipment assembly frame is made of aluminum alloy sections in building blocks way. It is designed and delivered in a modularized way, and can be immediately used on site.

Intelligent design: intelligent software with proprietary intellectual property has been used for analog simulating the system status and the filtering effect, guaranteeing usage effect of the equipment.

Design accuracy: site data testing is continuously executing before design and effect testing after operation, guaranteeing precision of the product design.

MSVC devices can achieve high precision compensation and the system power factor can be persistently set at a set value (such as 0.999);

Voltage class of MSVC device can reach 110kV, and can achieve dynamic powerless adjustment of 110kV system.

Controlling element of magnetically controlled reactor is low voltage thyristor of which the terminal voltage is only about 1% to 2% of the voltage of the whole system, no parallel connection is needed and it does not need to bear high voltage and heavy current. Therefore, MSVC devices are safe and reliable. The thermal power is relatively small and maintenance sot is relatively low.

Controllable silicon motion; harmonic wave produced out of commutation control will not flow into the exterior alternative current system. Therefore, harmonic wave produced by the MSVC devices is relatively quite small.

Even if the controllable silicon or diode tube was damaged, the magnetically-controlled reactor only amounts to a no-load transformer, not affecting operation of other devices. Therefore, reliability of the MSVC devices is high.

The economic advantages are obvious: maintenance in later period is free; structure of the MCR is simple, occupying relatively small land and the fundamental investment has greatly been condensed.

MSVC devices controller apply full digital intelligent controlling way, powerful in function, strong in scalability and they can greatly reduce the time for debugging, maintenance and overhauling.

Controlling ways of MSVC devices are rich and they can adapt to various operation ways of the main transformer.

It has strong self-diagnosis capacity: self-diagnosis in static state, dynamic monitor functions in operation, and they can generate accurate pre-warning and protection function to various emergencies in the system.

The devices apply micro-computer protection, including protection to phenomenon such as quick-break, over-current over-voltage, imbalance and over-run of harmonic wave.

Optical fiber controlling method is applied; the high-voltage part and the controlling part are in complete photo-electric isolation state and can operate well under strong interference and strong harmonic wave condition.

Controlling system of MSVC devices provide various communication interfaces and communication stipulations: they can connect with the comprehensive automatic system of the upper monitor through RS485/RS232, to achieve functions such as remote controlling, measurement, display and printing; and the automatic degree is comparatively high.

MSVC Devices Controlling System